Was it time for another boat? In the 1980s, it was a 16′ sailing dinghy that awakened my wife Barbara and me to the beach-cruising pleasures of the San Juan Islands in Washington’s Puget Sound. In the ’90s, it was a 19′ lug-rigged double-ender for oar, sail, and outboard that extended cruising to Desolation Sound. Then came a 20′ catamaran, sporting a wing mast with square-topped mainsail, that got us inside a comfortable cabin while offering exciting sailing in moderate conditions. But as years went by, sitting out in the weather and hauling sheets took its toll. Sailing was exciting when the wind was up, but boring in light summer winds. Why bother with sailing if we could motor at 10 knots? Was it time for a gasser?And so it was, and we decided upon the Eco 5 Power Cat by Bernd Kohler in France. Its narrow hulls, wave-piercing bows, space-age profile, and three-tone color scheme really made it a looker. At 5.5 meters, it was about the same size and accommodation as our 6-meter sailing cat, and still trailerable behind our compact SUV. The twin 5-hp outboards specified in the plans were to drive the EcoCat at an economical 10 knots and spin it around in circles. Having them mounted on the transoms should eliminate weed pickup, as well as the between-hull wave buildup working against a centrally mounted outboard. I ordered plans, and the digital files came quickly via email.The plywood-on-frame EcoCat is simply built, using chines sprung around widely spaced bulkheads. I opened the DXF files on an older Mac Cube still running Drawing Board CAD from Ashlar Vellum. With CAD, I made some design changes for a bit more cabin headroom, bigger windows, storage lockers forward, and extended cockpit sides complementing the cabin profile.

Join The Conversation

We welcome your comments about this article. To include a photo with your remarks, click Choose File below the Comment box.

Comments (27)

Comments are closed.

I would really like to see a drawing of the modifications mentioned in the text. It sounds like the end product was significantly different from the original design.

Tim, JUST ENUF is built exactly to the furnished plans. Obvious additions were the cockpit sides and transom extensions when repowering. Plans are furnished as DXF files which may be printed out for “manual parts layout” or modified in CAD for CNC cutting. I hope this helps.

Form definitely follows function on your well built boat. The 20-hp outboard was a great idea and so were all of the modifications to get everything right.

Pete, thanks for your kind thoughts. Looking forward to seeing you on a Salish Sea beach soon!

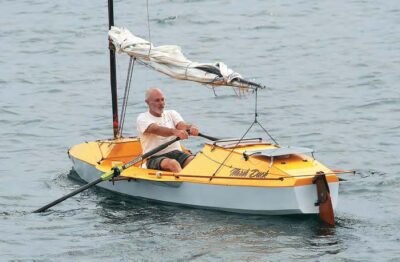

I really enjoyed the article in the March issue of Small Boats Monthly about Ron Mueller’s JUST ENUF. Ron’s boat never fails to draw all kinds of attention when he’s pulled out on the beach or running with a group of other boats up here in the north Puget Sound, and looking carefully at his superlative build, one can easily see why. Though I am somewhat of a “traditionalist” at present, this boat looks like it could very well be in my build list sooner rather than later!

I love seeing articles from other Salish Sea folk. The photo with Mount Baker (Komo Kulshan is the name given to it long ago by the Lummi people) in the background is part of my life.

Vince, twins seem desirable but two 8.5-hp motors would use noticeably more fuel then a single 17-hp motor. Remote control would lend itself to a autopilot but complicated. Remember that each catamaran hull has a different turning radius in a turn. My previous sailing Jarcat had rudders set up with Ackerman steering (like a car). That’s probably not really needed for outboards. Just a thought.

I like the look of this craft. What would be the result if you went to twin 8.5-hp outboards which have the electric start and hardware to do twin rigs with remote control? Still the design appears to have a lot going for it. Enjoy it!

I’m just wondering if the deadrise at the end of each original hull was maintained on the 1′ extensions and if so, how the trim tabs were installed.

Mike, deadrise was just flowed out. The trim tabs are a solid wedge at the end of the hull about 4″ long and 1″ thick. An end plate (in line with hull side) contains the water flow for greater effect. The end plate is a skeg-like shape about 12″ by 4″ that provides better tracking than the original skegs on the keel centerline.

Most of the changes Ron made to the design—the hull extensions and other modifications—are incorporated in the plans. There are many ECO’s sailing world wide and it is my policy to update the plans to improve my designs. That applies not only for my ECO line of boats, but the others as well.

By the way, I leveled out the deadrise of the extension to 0°.

Do the plans show the unique assembly method in case a builder wanted to have the parts CNC

cut? Is the interior of the cabin also coated with epoxy?

Most parts were pre-coated and sanded (at least one side) prior to assembly. The plans are DXF files for display and would need to be, at least, nested for a CNC tool path prior to cutting. After importing to a CAD program, I added an inch in cabin height. Enlarged the windows, laid out cubby holes in the forward bulkhead and designed the cockpit sides with the same curvature used for the cabin. This is a real timesaver and provides great accuracy when having symmetrical parts and provides very smooth curves. The planking and cabin top is best (and easily) laid out directly on existing structure rather then CNC cutting. The construction was completed in just four months while attending to my normal business of selling rowing shells and making kits of same. Painting and canvas was “sent out” and fitting out was, at least, another month.

Thank you very much.

What is the contraption mounted on the forward hatch?

It’s a Nicro Solar Vent Fan. It runs mostly 24/7 as long as its self-contained battery is charged. There is enough leakage through the companionway hatch to keep the cabin dry during winter storage and summer nights when we’re sleeping aboard. We usually slide the main hatch open an inch or two at night (the dodger protects it from rain), and latch the foredeck vent hatch open rather the use the fan. Although fans may be quiet at first, they do develop a bit of noise after a few years.

Thank you.

I did some measuring. I wouldn’t have the ceiling height to flip the hulls over. Is there a real problem building them separately?

Walter, good news, the hulls are built separately. While the hulls were still upside down, I coated them with three coats of epoxy mixed with graphite powder. Those are the black surfaces in the video. This graphite/epoxy mix becomes “bottom paint” and is quite UV resistant, and does not need further painting.

The hulls are then rotated upright, aligned, and a 1/2″ plywood deck is glued to join both hulls. Everything else is built up from this deck—no need to turn the boat over! All of the painting is done from the waterline up. You could paint the bridge deck underside and inner hull sides while the boat is on a trailer.

What brand of windlass was used on JUST ENUF?

An 11-pound Bruce anchor with 10′ of chain is quite easy to haul with an arm-power winch while standing in the forward hatch.

I was looking at the thing below the hatch. Again, thank you.

Appromately how many sheets of plywood were CNC cut?

CNC cutting was used for all bulkheads, frames, cabin sides, cockpit sides, and interior trim— perhaps 10 sheets. The advantage of CNC is symmetrical parts, identical parts for both hulls and very smooth curves and cutout radius. When I had it (now retired six years), my ShopBot was the power tool of choice. Whatever I drew, I could cut and it would fit! Really miss it for my infrequent annual boat building project.

PS: The “thingy” below the hatch was a simple anchor bow roller.

Ron,

Thank you very much for the information. I have found a local shop that has two ShopBot machines with the capacity of 66″ x 122″.

Greetings Ron, and congratulations on a well built project with very intelligent, yet simple modifications. My question is: Why were not twin 10-hp outboards considered when the twin 5s were insufficient instead of the single 20? Weight, perhaps? And could not the weight vs performance equation also be solved with transom trim tab re-engineering or re-positioning of gas tanks, etc?

Love this boat. I am in Biscayne Bay, Forida. We get a chop, we get wind, squalls, hurricanes, etc. It’s a very open bay, but then we get to cruise to the Keys, the Everglades archipelagos, and a million places to explore and gunkhole. I have owned several sailboats here, all with retractable keels—a must if you’re on the bay and want to get off the beaten path of all the Olympic and Biscayne Bay Yacht Racing Association regattas.

Twin 5’s were specified as it was to be a EcoCat. The Honda 9.9 weighs on or about 100 pounds. The Honda rep insists that a single outboard (equivalent in HP to two twins) will always be more economical. I’d suggest today’s best choice would be a Suzuki 25, about the weight of the Yamaha 15/20. It’s said to be more economical and quieter. They sell a 30 (same block size) in the US but it only comes with power trim/tilt so the bracket would be dragging in the water. I hope this helps.